|

|

What are the characteristics of deep hole drilling, common problems can be solved in this wayDeep hole machining has always been a difficult point in post-mortem machining, and its proportion is indeed indispensable. At present, in cutting processing, hole processing accounts for about 1/3 of the total processing, and deep hole processing accounts for 40% of hole processing! The general definition of deep hole is: the ratio of deep hole is L/D (the ratio of the depth dimension of the hole to the radial dimension of the hole is called the depth-diameter ratio of the hole) ¡Ý 6 is a deep hole!

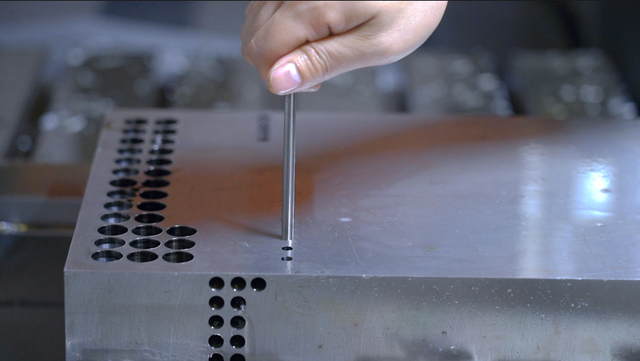

Ligong deep hole drilling Processing characteristics of deep hole drilling: The cutter bar is limited by the aperture, the diameter is small, and the length is large, resulting in poor rigidity and low strength. It is easy to generate vibration, ripple and taper during cutting, which affects the straightness and surface roughness of the deep hole. When drilling and reaming, it is difficult to input the cooling lubricant into the cutting area without using special devices, which reduces the durability of the tool and makes chip evacuation difficult. In the process of deep hole machining, it is not possible to directly observe the cutting condition of the tool, but to judge the cutting process by listening to the sound of cutting, watching chips, hand vibration and workpiece temperature, and observing instruments (oil pressure gauge and electric meter) based on work experience. Is it normal. Chip removal is difficult, and reliable means must be used to break chips and control the length and shape of chips to facilitate smooth removal and prevent chip clogging. 5. In order to ensure the smooth progress of the deep hole and the required processing quality during the machining process, the inner (outer) chip removal device, the tool guiding and supporting device, and the high-pressure cooling and lubrication device should be added. Common problems and solutions: Rough surface of the hole 1. Chip adhesion: reduce cutting speed; avoid chipping; switch to cutting fluid with high extreme pressure, and improve filtration; increase the pressure and flow of cutting fluid. 2. Poor coaxiality: adjust the coaxiality between the machine tool spindle and the drill sleeve; use an appropriate drill sleeve diameter. 3. The cutting speed is too low, the feed rate is too large or uneven: use the appropriate cutting amount. 4. Inappropriate tool geometry: change the geometric angle of the cutting edge and the shape of the guide block, and the orifice is flared. Poor axiality: adjust the coaxiality of the machine tool spindle, drill sleeve and support sleeve; use an appropriate drill sleeve diameter, and replace the drill sleeve with excessive wear in time.

The drill is broken 1. The chip breaking is not good, and the chips cannot be discharged: change the size of the chip breaker to avoid being too long and shallow; find the chipping situation in time and replace it; increase the pressure and flow of the cutting fluid; use workpieces with uniform material structure . 2. The feed rate is too large, too small or uneven: use the appropriate cutting amount. 3. Excessive wear of the drill bit: Replace the drill bit regularly to avoid excessive wear. 4. The cutting fluid is not suitable: select the appropriate cutting fluid and improve the filtration. bit life is low 1. The cutting speed is too high or too low, and the feed rate is too large: use the appropriate cutting amount. 2. The drill bit is not suitable: replace the tool material; change the position and shape of the guide block. 3. The cutting fluid is not suitable: switch to a cutting fluid with high extreme pressure; increase the pressure and flow of the cutting fluid; improve the filtration of the cutting fluid. |